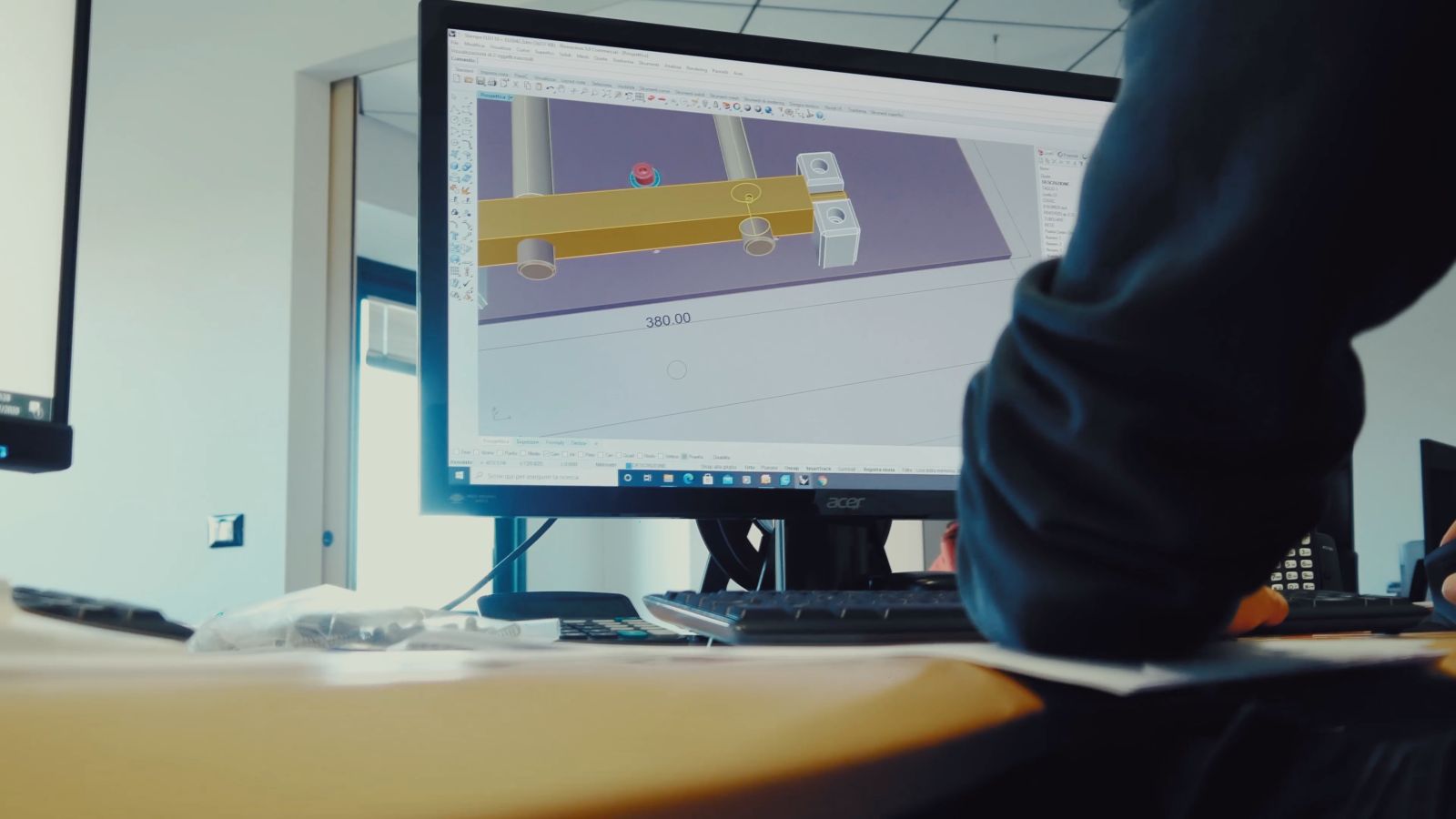

We have an in-house design office with CAD/CAM modelling software and a production department equipped with state-of-the-art CNC machining centres, enabling us to produce high-performance moulds for high-frequency welding and thermoforming.

Our technicians work together with our customers to find the best solution based on the requirements of their application, allowing us to create complete moulds and to ensure a timely after-sales service.

We are also able to supply single blades, die cutters or hangers, as well as the insulating materials required for high frequency welding, such as Mylar, Vetroteflon, lacquered Polyfilm and Vetronite.

Request support from our technical office for the design of moulds for HF welding.

Quality moulds for high frequency welding

Our production process for moulds

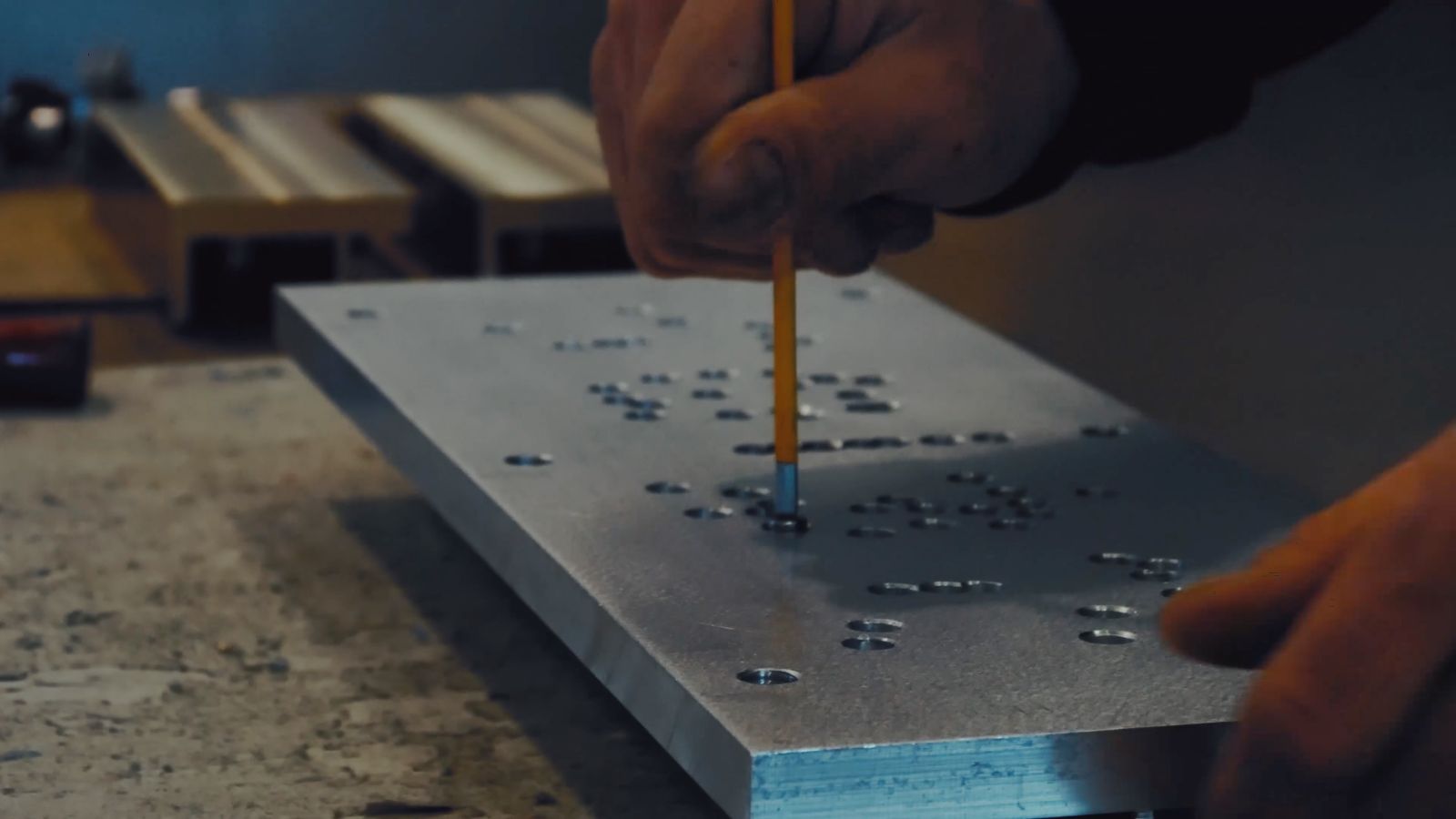

We oversee every mould from the original technical designs to the final checks, working with our customers to find solutions that optimise batch production and take account of critical aspects of application. In this way, we can guarantee high quality moulds for HF welding and offer effective support for everything related to high frequency welding.

Design

Mould production

On request, we can also make a prototype resin model.